High Temperature Furnaces

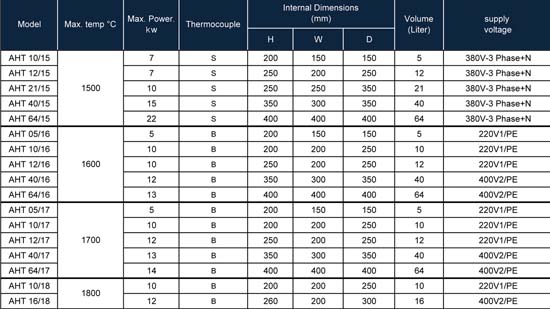

Technical Data

Applications:

Suitable for wide

variety of applications such as research laboratories,

cement industry, ceramics, composites, sintering of refractory materials,...

Type:

Front loading with parallelogram type door movement or

elevator hearth

Max. temperature:

1600°C, 1700°C, 1800°C

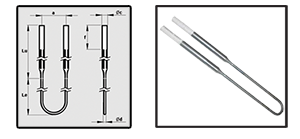

Heating Element Type:

High-quality MoSi2 heating elements

Inner chamber and door: High grade insulating ceramics boards

Thermocouple:

Type B thermocouple

Loading:

On

the bottom of the furnace/ bogie hearth furnace

Power system: Zero cross switching system by triac and thyristor and without any disturbing harmonics

Safety system: Over-temperature limit controller with sonic alarm

Specification:

● Low weight and compact

design

● Minimum thermal loss

and low power consumption

● Improved temperature

uniformity in high temperature applications

● Two layered insulation

for low external temperature and stability

● Fast heat up and short

cooling down period

● Optional protective

gas connection on the wall of furnace for inert gases (Ar, N2, …)

/ reducing or oxidizing atmosphere