CNG Cylinders Hardening Line

CNG Cylinders Hardening Line:

● The line is comprised of three main parts:

1- Hardening furnace

2- Automatic quenching tank

3- Tempering furnace

● Capable of charging CNG cylinders in different sizes and weights

● Continuous with adjustable motion pace

● Gas fired heating system

● No direct contact of flame with the surface of treated parts

Hardening Furnace

● Gas fired heating system

● Continuous walking beam type

● Maximum temperature: 1100°C

● With preheating and soaking zones

● Low surface oxidation

● Automatic cylinder charging and discharging tables

Automatic Quenching Tank

● Automatic immersion and extraction of the cylinders

● Affording various quenching methods

● Equipped with the cooling and heating systems

● Suitable agitation inside the quenching tank

Tempering Furnace

● Gas-fired heating system

● Continuous movement with conveyor or walking beam systems

● Hot air circulation system to reach to the best thermal uniformity

● Maximum operating temperature of 750°C

● Including preheating and soaking zones with excellent thermal

uniformity

● No direct flame contact with treated parts

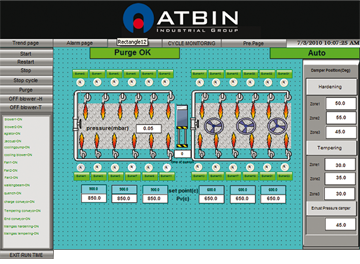

PLC-controlled Automation & Monitoring System:

Capabilities of this system are:

● Temperature control and display of actual and set temperatures

graphs in each zone

● Display of burners status

● Display of temperature graphs for each zone (Temperature-Time graph)

● Data recording such as temperature, pressure, ...

● Display of doors status

● Display of system motion performance

● Display of motor fans mode (On/Off)

● Display of PLC operation option (Manual/Automatic)

● Alarming in cases of air pressure drop, gas pressure

drop/rise, temperature rise in each zone, burner

turn off and PLC malfunction